5052 0 Aluminum Specs

Mirror like sheets and bars are polished to a 8 reflective finish and are free of grain lines.

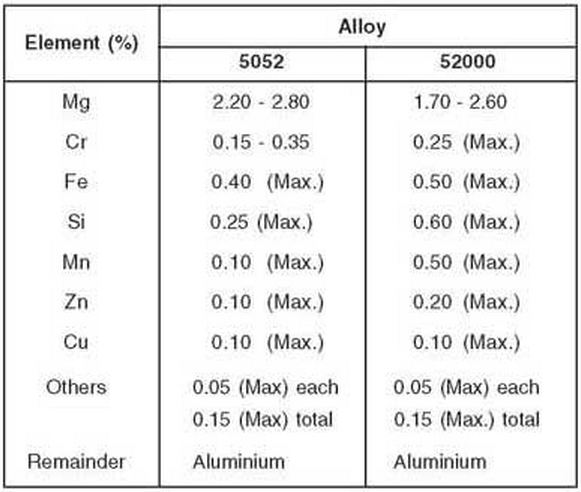

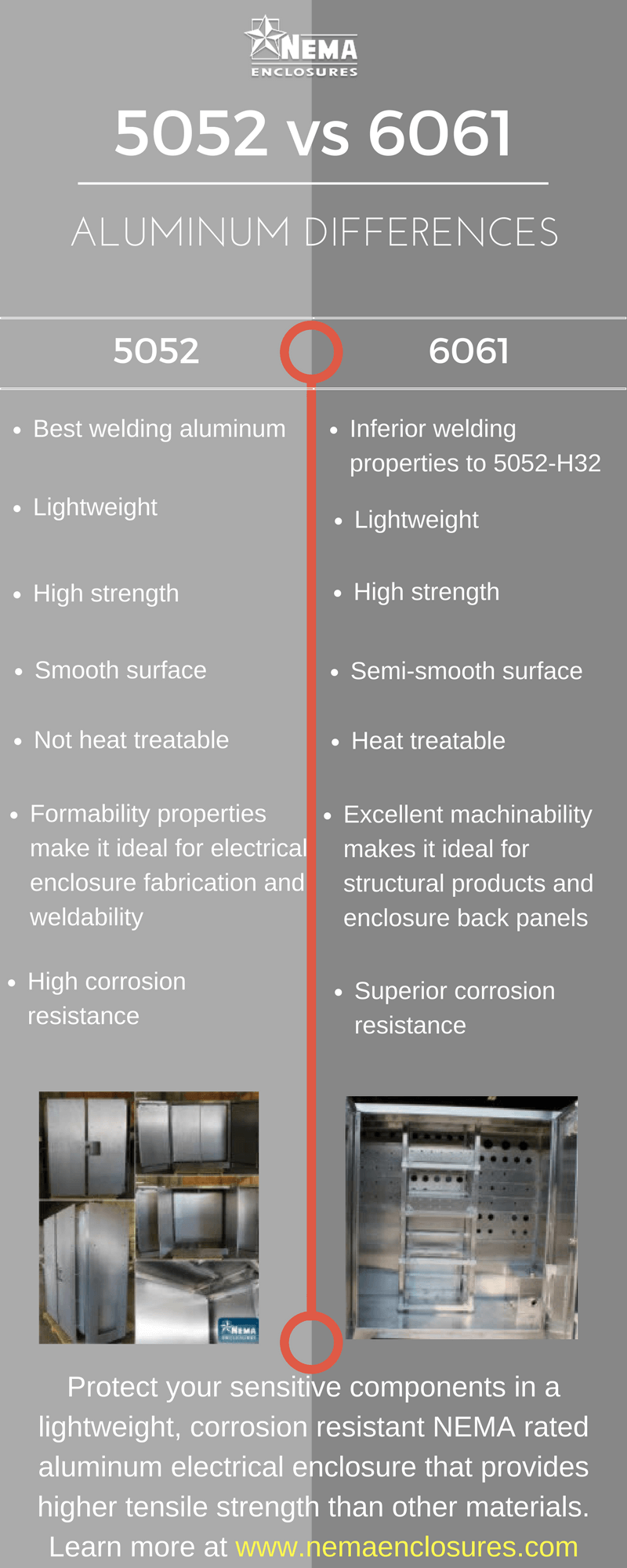

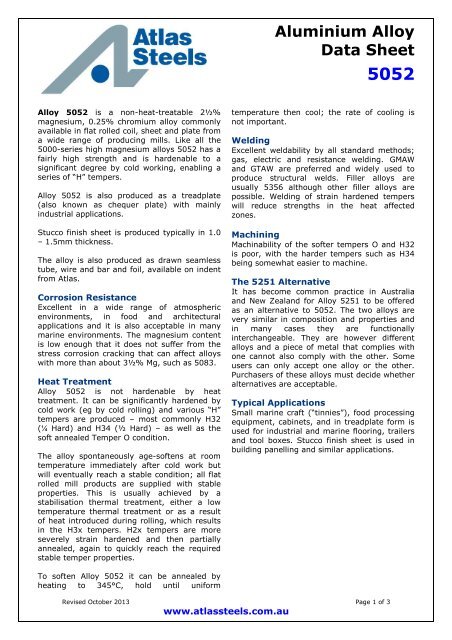

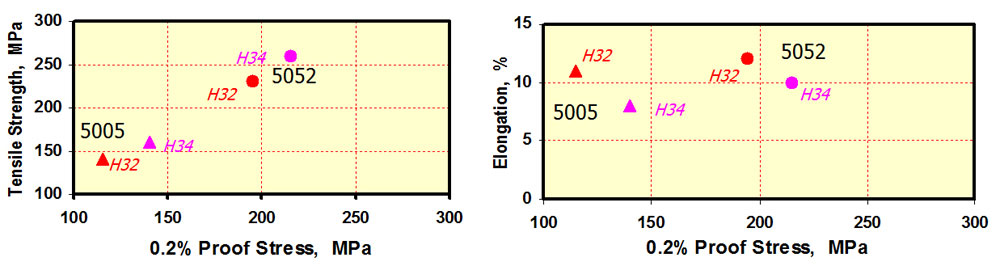

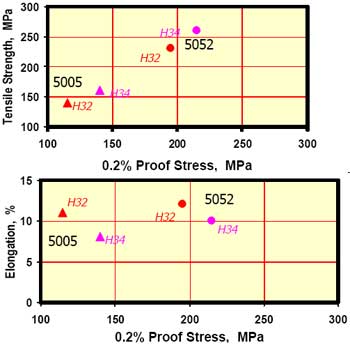

5052 0 aluminum specs. It has very good corrosion resistance and can be easily welded as well. Aluminium alloy 5052 contains nominally 2 5 magnesium 0 25 chromium. Description aluminum alloy 5052 contains nominally 2 5 magnesium 0 25 chromium and has good workability medium static strength high fatigue strength good weldability and very good corrosion resistance especially in marine atmospheres. For each property being compared the top bar is 5052 h32 aluminum and the bottom bar is 5052 o aluminum.

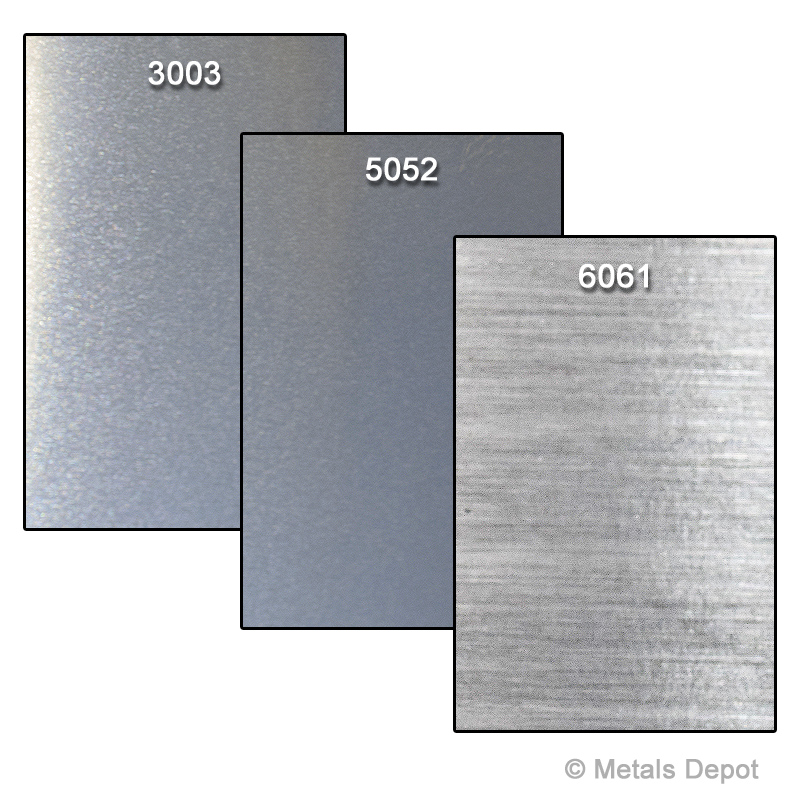

Product data sheet aluminium 5052. 5052 is the aluminum alloy most suited to forming operations with good workability and higher strength than that of either 1100 or 3003. It also has the low density and excellent thermal conductivity similar to other aluminum alloys. Generally 5052 aluminum alloy is stronger than other popular alloys such as 3003 aluminum and also has improved corrosion resistance due to the absence of copper in its composition.

They share alloy composition and many physical properties but develop different mechanical properties as a result of different processing. Known for being one of the easiest types of aluminum to weld 5052 is also recognized for its ability to resist salt water. It s widely used for the bodies of boats buses trucks and trailers as well as for chemical drums. Tw has a wide range of sizes readily available to the ams 4015 for o temper ams 4016 for h32 and ams 4017 for h34.

Our federal specifications ww t 700 4 drawn 5052 0 aluminum tube speaks for itself and you probably wouldn t be reading this if you didn t need some quality aluminum tubing for an important aviation project. Federal specifications ww t 700 4 drawn 5052 0 aluminum tube. It has some important advantages when compared to steel it weighs less provides exceptional resistance to corrosion and has the strength required for many aircraft uses. Rigid 5052 0 aluminum alloy tubing is used for low and medium pressure hydraulic systems fuel lines and oil lines.

This tubing will withstand a higher pressure than 3003 0 tubing. Type 5052 aluminum contains 97 25 al 2 5 mg and 0 25 cr and its density is 2 68 g cm 3 0 0968 lb in 3. 5052 is not a good choice for extensive machining operations as it has only a fair machinability rating. 5052 is not heat treatable but is stronger than most of the 5xxx series of aluminums.

Aluminium development council of australia. Brushed sheets and bars are polished to a 4 satin finish with grain lines running in one direction to mask fingerprints. 5052 aluminium 5052 is the alloy most suited to forming operations with good workability and higher strength than that of the 1100 or 3003 alloys that are commercially available. It has good workability medium static strength high fatigue strength good weldability and very good corrosion resistance especially in marine atmospheres.