Autodesk Inventor Sheet Metal K Factor

By default inventor uses a k factor for calculating bend allowances.

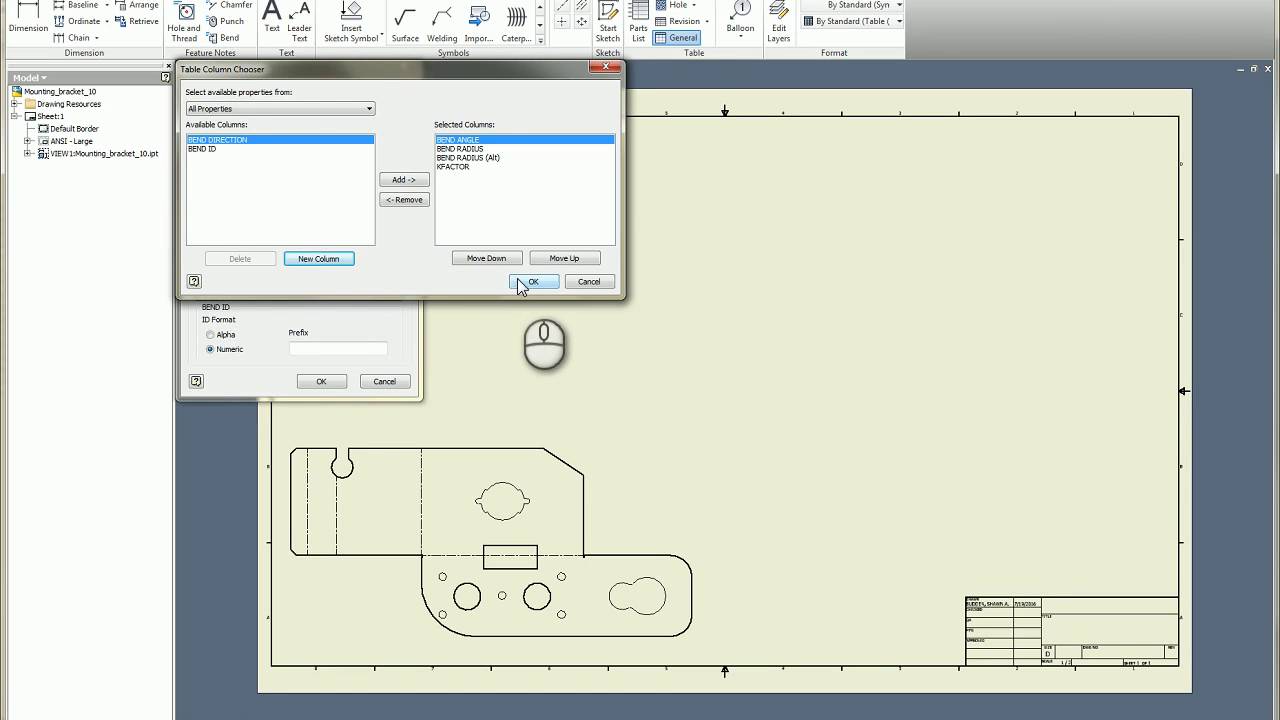

Autodesk inventor sheet metal k factor. Get answers fast from autodesk support staff and product experts in the forums. A bend table is a table of bend deductions arranged in rows and columns. Each column specifies a bend radius. Access the material editor to make edits to a material not available in.

Share and vote on ideas for future. Select bend table as the unfold method. I don t even know if you could enter a 0 0 for a k factor in inventor possibly something like 0 0000000000001 or it could be 1 0. Notice that the right hand portion of the dialog box updates to provide an.

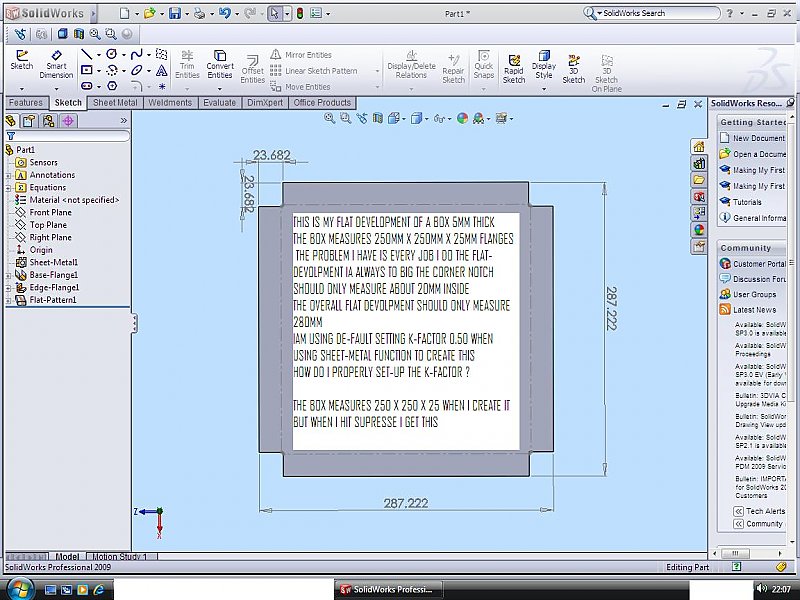

Using a bend table. Each row in a bend table specifies a bend angle. So if the thickness of the sheet was a distance of t 1 mm and the location of the neutral axis was a distance of t 0 5 mm measured from the inside bend then you would have a k factor of t t 0 5 1 0 5. This video explains the process of importing an excel file saved as txt into autodesk inventor for bend allowance bend deduction calculation.

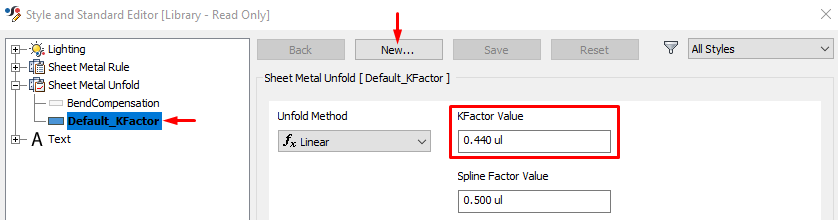

Except where otherwise noted work provided on autodesk knowledge network is licensed under a creative commons attribution noncommercial sharealike 3 0 unported license. The default k factor is 0 44 which simply means that inventor is assuming that 44 through the cross section of the part the material is not stretched or squashed when bending and therefore this slice of the folded part will give the true length of the flat pattern. When unfolding if a bend radius or angle does not correspond to a specific entry a process interpolates between adjacent values in the table. Access the style and standard editor to make edits to an unfolding rule or to set a new active standard rule.

Sheet metal k factor. Inventor forum sheet metal k factor. K factor a constant determined by dividing the thickness of the sheet by the location of the neutral axis which is the part of sheet metal that does not change length. Michael davis owner of ycg inc.

Use the sheet metal defaults dialog box to change the options and parameters defined by the selected sheet metal rule for the active sheet metal part or to assign a unique thickness to a body in a multibody part. Values for angles not defined within the table are calculated using a backup kfactor. Using the bend table unfolding method sheet metal parts unfold using empirical values that are measured or derived and applied to specific bend angles within the table.